Craftmanship

Craftsmanship is the heart and soul of De Glint, a critical element that sets us apart.

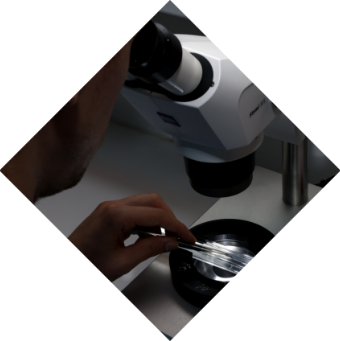

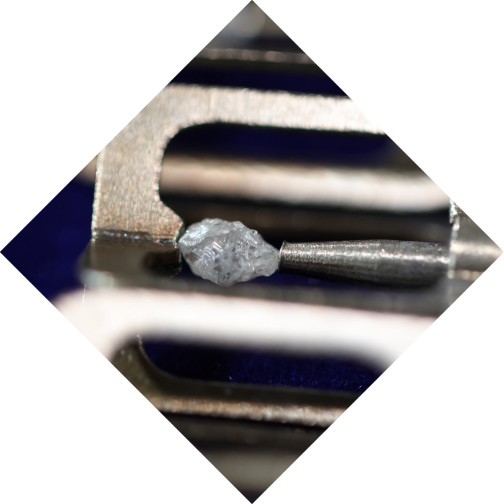

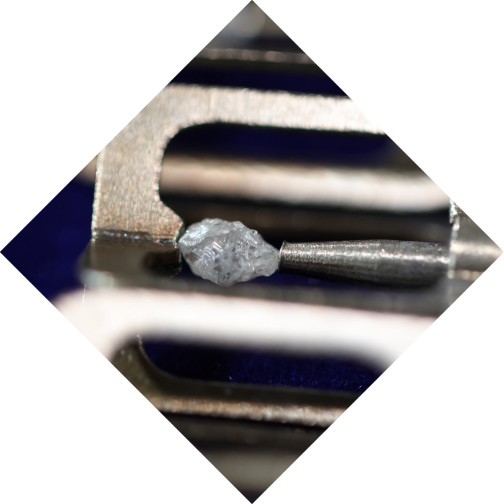

Every mined diamond is unique in shape, size, and inclusion. Mastering these unique traits requires a deep understanding and strategic approach to cutting and polishing, aimed at maximizing each diamond’s potential.

Our strengths

- Education: We foster a comprehensive understanding of diamond anatomy, cutting and polishing techniques, the laws of reflection and refraction, and complex geometric fundamentals. This knowledge base is fundamental to our craft.

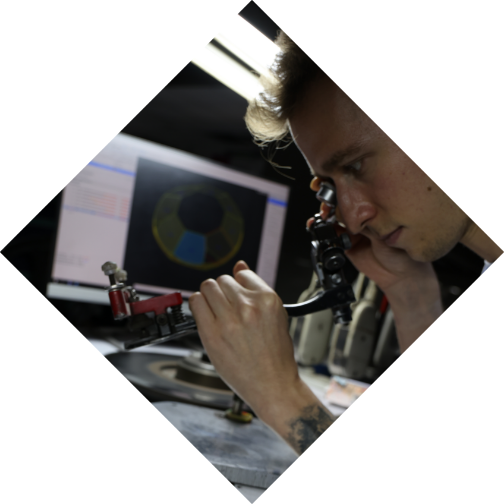

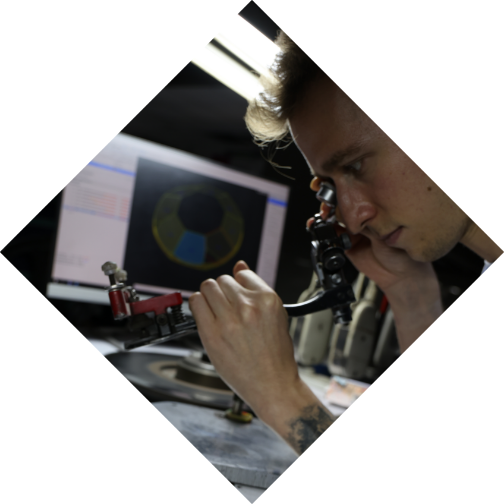

- Muscle Memory: Precision is key. Our artisans possess finely-tuned control when working with tools, applying calculated pressure to minute facets through manual skill and practice.

- Experience: This is the backbone of perfection. The more diamonds our craftspeople work with, the more situations they encounter and overcome. This wealth of experience enables us to deliver increasingly precise results at higher speeds, harmoniously combining efficiency with excellence.

- Teamwork: Crafting a diamond involves a series of meticulous processes. It’s crucial that each step is flawlessly executed, synergizing with the steps that came before and those that will follow. Our team works seamlessly together, ensuring every process supports the next for a flawless final product.

At De Glint, craftsmanship is not just a skill, but an art form that we constantly perfect. It’s the journey from raw stone to shining jewel that truly captures our passion and dedication.

Technology

Our factory blends traditional craftsmanship with modern technology, striking a perfect balance between the human touch and machine precision. This fusion is what allows us to deliver diamonds of unparalleled quality.

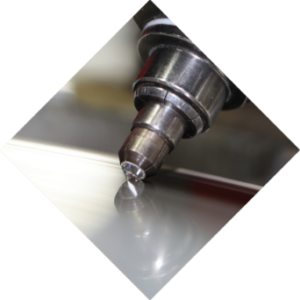

01 Swiss Water Jet Laser

Cutting Machinery

(Synnova Technologies)

Considered a global leader in precision, this machine can delicately cut a diamond of up to 1000 carats with the lowest risk of damage. Synnova’s laser cutting machinery represents the pinnacle of accuracy in the industry.

02 Sarine Technologies

At De Glint, we harness Sarine’s world-class technology for optimal mapping, planning, sawing, and polishing solutions. Our factory is equipped with Sarine’s finest machines, including the GALAXY for mapping, Dia Expert for Planning, Quazer for Sawing, and Dia Mension for polishing.

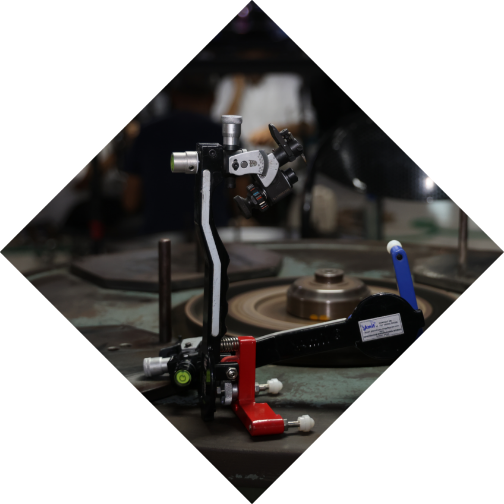

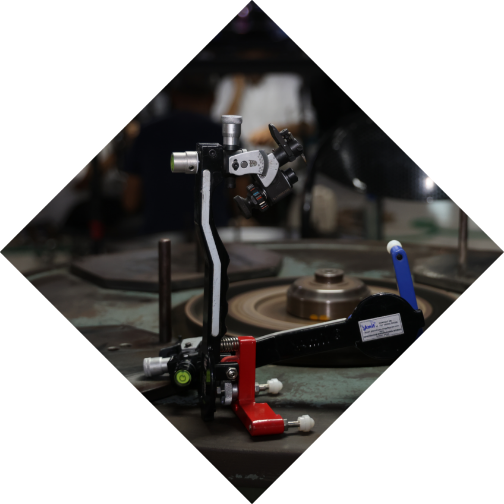

03 Galahad Compass

This state-of-the-art diamond polishing tool significantly enhances accuracy and productivity. Designed with user-friendliness in mind, the Galahad Compass is an invaluable asset in mastering the art of diamond polishing.

04 DIALIT (GS7000-E model) - Auto Polishing Diamond Tool

In an era where skilled manual labor is increasingly rare, we’ve adopted automated solutions to stay ahead. The DIALIT GS7000-E boasts four robotic arms for precision diamond polishing. Yet, we recognize the irreplaceable value of human touch – the ability to make split-second micro-decisions, a testament to the power of muscle memory in our industry.

05 Accurate Diamond Polishing Dopes: RICO and AMIT

We believe the best results require the best tools. RICO and AMIT dopes are top-tier tools for diamond polishing, harmonizing perfectly with our artisans’ muscle memory to yield exquisite results.

06 Helium Diamond Cut Grading Machine: Precision at its finest

The Helium Diamond Cut Grading Machine optimizes a wide range of parameters to deliver the finest cuts. Its grading reports align perfectly with GIA cut grading standards, ensuring our diamonds meet globally recognized excellence benchmarks.